Description

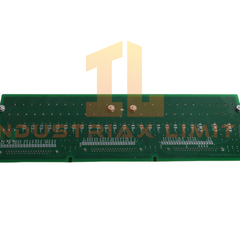

Product Overview

The GE IS215VAMBH1A Acoustic Monitoring Board from the Mark VI Series delivers high-speed signal conditioning and analysis for turbine acoustic diagnostics. It supports 18 input channels via two IS200TAMB terminal boards and integrates seamlessly with third-party charge amplifiers like Bentley Nevada, Vibro-meter, and GE/Reuter-Stokes.

This board features differential inputs, adjustable gain settings, and FPGA-based preprocessing with FIR filters. It performs real-time RMS calculations and peak amplitude alarms across all channels, ensuring precise monitoring of dynamic pressure signals.

Technical Specifications

| Parameter |

Specification |

| Part Number |

IS215VAMBH1A |

| Series |

Mark VI |

| Voltage |

24 V DC |

| Current Range |

20–60 mA |

| Dimensions |

300 mm × 50 mm × 180 mm |

| Weight |

0.8 kg |

Signal Processing Features

-

18-channel synchronous analog/digital sampling with 8x oversampling

-

FPGA preprocessor with FIR filtering and open wire detection

-

RMS value calculation and configurable peak alarm detection

-

List capture capability triggered by alarm events

-

Supports differential input from third-party charge amplifiers

-

Power supply options include +24V or -24V via IS200TAMB or external source

Application & Compatibility

Use the IS215VAMBH1A board in gas turbine frames 6, 7, or 9 for acoustic monitoring and diagnostics. It connects to one or two IS200TAMB terminal boards and supports integration with sensors from PCB Piezotronics, GE PS CCSA, and other vendors.

Ideal for vibration analysis, combustion monitoring, and dynamic pressure sensing in industrial turbine environments.