Description

Product Overview

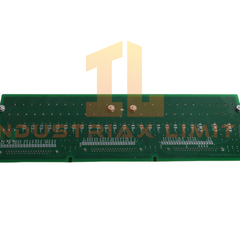

The IS200TSVOH1BDC Servo Terminal Board from General Electric belongs to the EX2100 Mark VI Series. This PCB weighs 0.56 kg and measures 33 x 17.7 x 2.5 cm, offering reliable integration into turbine control systems. Engineers value its LVDT-based valve position feedback, multiple coil support, and jumper-selectable current sources for precise control in demanding environments.

Technical Specifications

| Parameter |

Value |

| Model Number |

IS200TSVOH1BDC |

| Module Type |

Servo Terminal Board |

| Manufacturer |

GE |

| Product Range |

EX2100 / Mark VI |

| Condition |

Brand New |

| Weight |

0.56 kg |

| Dimensions |

33 x 17.7 x 2.5 cm |

| HS Code |

8537101190 |

| Minimum Order Quantity |

1 |

| Origin |

USA |

| System |

DCS |

| Status |

Active |

| Communication Service |

Ethernet router |

| Terminal Blocks |

Two, 24 terminals each (#12 AWG) |

| Connectors |

J3, J4, JR1, JS1, JT1, JD1, JD2 |

| Channels |

Servo current, LVDT feedback, excitation, pulse rate flow |

| LVDT Inputs |

Up to six per control loop |

| Cable Resistance |

15 ohms max, 300m length |

| Coil Support |

One–three coils per output channel |

| Jumpers |

JP1–6 for coil current selection |

Functional Description

The IS200TSVOH1BDC board connects directly to electro-hydraulic servo valves that regulate steam and fuel valves. Engineers benefit from its four functional channels: bi-directional servo current outputs, LVDT position feedback, LVDT excitation, and pulse rate flow inputs. Up to six LVDT valve position inputs per control loop ensure precise turbine control.

Two I/O terminal blocks with 24 screw-secured terminals simplify wiring, while shield termination strips provide grounding. In Simplex setups, one or two coil servos per channel are supported, while TMR configurations accommodate up to three coils. Jumper-selectable current sources allow flexible coil configurations, and external trip wiring is routed through JD1 or JD2 connectors.

Applications and Compatibility

The IS200TSVOH1BDC Servo Terminal Board suits turbine excitation systems, industrial automation, and safety-critical monitoring networks. It integrates seamlessly with GE Speedtronic EX2100 and Mark VI assemblies, ensuring compatibility across diverse environments. Engineers deploy it in power generation plants, heavy industry, and automation networks where precise valve control and reliable LVDT feedback are essential.