Description

Overview

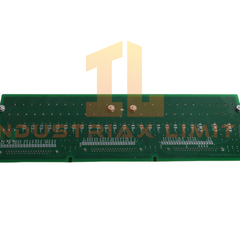

The GE IS200EDCFG1A Exciter Direct Current Feedback Board is a critical component of the EX2100 control system. Engineers use this board to measure field current and voltage at the SCR bridge with precision. Its fiber-optic communication ensures fast, isolated, and noise-resistant data transmission, making it ideal for demanding industrial environments.

Technical Specifications

| Parameter |

Value |

| Model Number |

IS200EDCFG1A |

| Module Type |

Exciter Direct Current Feedback Board |

| Manufacturer |

GE |

| Product Range |

Multilin / EX2100 |

| Condition |

Brand New |

| Lead Time |

In Stock |

| Weight |

0.24 kg |

| Dimensions |

22.8 x 15.1 x 3.5 cm |

| HS Code |

8537101190 |

| Minimum Order Quantity |

1 |

| Origin |

USA |

| System |

DCS |

| Status |

Active |

| Communication Service |

Ethernet router |

| Fiber Options |

Plastic (10 m), Hard-Clad Silica (90 m) |

| Signal Transmission |

Separate fibers for current and voltage |

| Diodes/Capacitors |

Integrated for circuit stability |

Functional Description

The GE IS200EDCFG1A uses fiber-optic links to communicate with the EISB board, ensuring electrical isolation and immunity against electromagnetic interference. Engineers benefit from flexible fiber options, supporting both short-range plastic fiber and long-range hard-clad silica fiber. Each critical signal—field current and voltage—travels through separate fibers, minimizing interference and maintaining measurement accuracy.

Its compact design and lightweight build simplify installation, while integrated diodes and capacitors stabilize circuit performance. The GE IS200EDCFG1A enhances excitation control reliability, ensuring precise monitoring and safe operation in turbine systems.

Applications and Compatibility

The GE IS200EDCFG1A Exciter Direct Current Feedback Board integrates seamlessly with EX2100 turbine control systems. It suits industrial automation projects requiring accurate excitation feedback, fiber-optic isolation, and EMI resistance. Typical applications include gas and steam turbine excitation, power generation monitoring, and advanced DCS environments where precision and reliability are essential.