Description

Overview

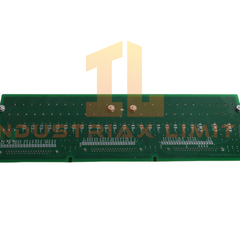

The Bently Nevada 330103-00-06-05-02-CN Controller Module delivers precise vibration monitoring and real-time analysis for industrial machinery. Its compact 10 × 2.6 × 14 cm dimensions and 0.42 kg weight simplify installation while ensuring stable performance. Engineers rely on this module to detect imbalance, misalignment, and wear early, reducing downtime and preventing costly failures.

Durable construction allows the 330103-00-06-05-02-CN to withstand harsh environments. Advanced signal processing ensures accurate data transmission, supporting predictive maintenance strategies and extending equipment lifespan.

Technical Specifications

| Parameter |

Value |

| Model Number |

330103-00-06-05-02-CN |

| Module Type |

Controller Module |

| Manufacturer |

Bently Nevada |

| Product Range |

3300 Series |

| Condition |

Brand New |

| Lead Time |

In Stock |

| Weight |

0.42 kg |

| Dimensions |

10 × 2.6 × 14 cm |

| Operating Temperature |

-40°C to +85°C |

| HS Code |

8537101190 |

| Minimum Order Quantity |

1 |

| Origin |

USA |

| System Compatibility |

TSI |

| Communication Service |

Ethernet router |

Functional Description

The 330103-00-06-05-02-CN Controller Module integrates seamlessly with Bently Nevada monitoring systems. Its advanced design provides accurate vibration data, enabling operators to act before mechanical issues escalate. The rugged build guarantees long-term performance in extreme industrial environments, supporting continuous machinery health monitoring.

By incorporating the 330103-00-06-05-02-CN into predictive maintenance programs, industries reduce repair costs, extend equipment lifespan, and improve operational efficiency. Its compatibility with the 3300 XL 8 mm Proximity Transducer System makes it a trusted solution for critical rotating equipment.

Applications and Compatibility

The 330103-00-06-05-02-CN Controller Module suits industries such as power generation, petrochemicals, and manufacturing. It integrates with the 3300 XL Proximity Probe and Transducer System, supporting vibration monitoring, machinery diagnostics, and predictive maintenance. Its robust design ensures dependable performance in demanding industrial conditions.